Heavy-duty fan coil units, Air Volume 600 to 2000 cfm for ducted application, are readily adaptable to a wide variety of installation applications in both new and old buildings. They are especially suitable for use in apartments, Hotels and Motels, Hospital, Office buildings and institutions. These fan coil units are offered in eight sizes with capacities that range from 600 to 2000 cfm [1020 to 3398m³/hr]. Virtually unlimited heating and cooling coil combinations, the fan coils utilize energy saving permanent split capacitor motors with oversize blowers, and have the ability to precisely match the units to the room requirements, providing maximum efficiency at minimum fan RPM. An unlimited selection of control systems is also available. They may be factory installed, to save on site time and dollars. American Pro® fan coil units are engineered and built with both job installation and operating economy in mind.

UNIT FEATURES

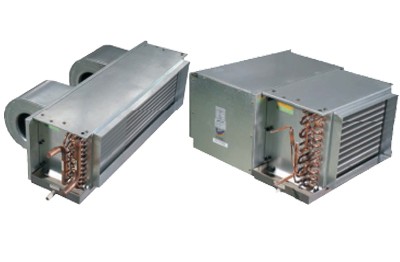

YC – HORIZONTAL BASIC UNIT

Designed for various concealed type installations, the horizontal basic unit is suitable for application such as drop ceiling or over closet in commercial establishment, hotel, motel, and apartment. The return air is via free return, with filters can be located at the return air grille, thus savings on the return air grille, thus savings on the return air ducting. Blower assembly is easily detached from the unit, thus allowing space for coil cleaning. Panels are constructed of minimum 1.0mm thick galvanized steel and

standard unit is galvanized finish.

YCQ – HORIZONTAL UNIT WITH PLENUM

Designed for installation requiring return air ductwork or simply as a return air plenum with filters. The unit maintains the same configuration as the basic unit but is furnished with return air plenum. The standard arrangement has one inch return

and supply duct collar and one-inch washable filter. Panels are constructed of minimum 1.0mm thick galvanized steel and standard unit is galvanized finish.

UNIT CONSTRUCTION

Standard unit consists of a coil, single-phase permanent split capacitor motor, blower and drain pan. Slots on the top panel of the unit are provided for hanging. Duct collar is standard for all supply air ducted units. Drain pan is insulated of close cell fire retardant

PE foam.

BLOWER ASSEMBLY

Units are equipped with one or two direct drive motor blower assemblies which are easily removed for complete servicing. The blower wheels are large in diameter and of the forward curved design, statically and dynamically balanced and operate at low rotation

per minute to assure smooth and quiet performance

MOTORS

Motors are 3-speed single phase permanent split capacitor type. Motor bearings are deep groove ball bearing and each motor is protected by thermal overload protector.

COILS

Available for chilled water and DX applications. Chilled water and DX coil consist of staggered rows of 1/2" [13mm] seamless copper tubes each. Coils are mechanically expanded into die-formed aluminum fins spaced 12 fins per inches [25mm]. Fins are of

corrugated design to improve heat transfer. Standard chilled water coils are of 3, 4 and 6 rows design. Standard DX coils are of 4 rows design. All coils are tested under water with 350 psig [24 bar] air pressure. Coils are furnished with a vent and drain connection.

Every coil is computer optimized selected to ensure best selection to reduce operating cost and ensure low first cost.

DRAIN PAN

The drain pan is constructed of heavy gauge metal and is internally painted with mastic and externally insulated with minimum 6 mm thick fire-retardant PE foam. As the condensate is prevented to be in contact with the metal the possibility of corrosion is minimized. The unit is designed, when mounted level, to assist condensate draining by having a positive pitch. This in conjunction with an adequately sized drain connection assures rapid condensate runoff.

FILTERS

Standard flat filters are 1" [25mm] washable type. The filter media is constructed of 70% arrestance efficiency synthetic fiber.

ACCESSORIES AND OPTIONS

· Extended drain pan

· On/ off two way valve

· Threaded water inlet and outlet connection

Need Any Help, Call Us 24/7 For Support

San Dimas, USA